DID1 Standalone ECU Wiring and Software Calibration for Kubota engine

We were tasked to build a complete wiring loom for an engine test bed by a local company in the Netherlands who specialise in rebuilding engines for plant machinery.

They were able to test old engines, but the newer engines with common rail systems needed an ECU and a wiring loom.

It would not be cost effective to buy each ECU and wiring loom from the manufacturer just to test engines because there are so many different types.

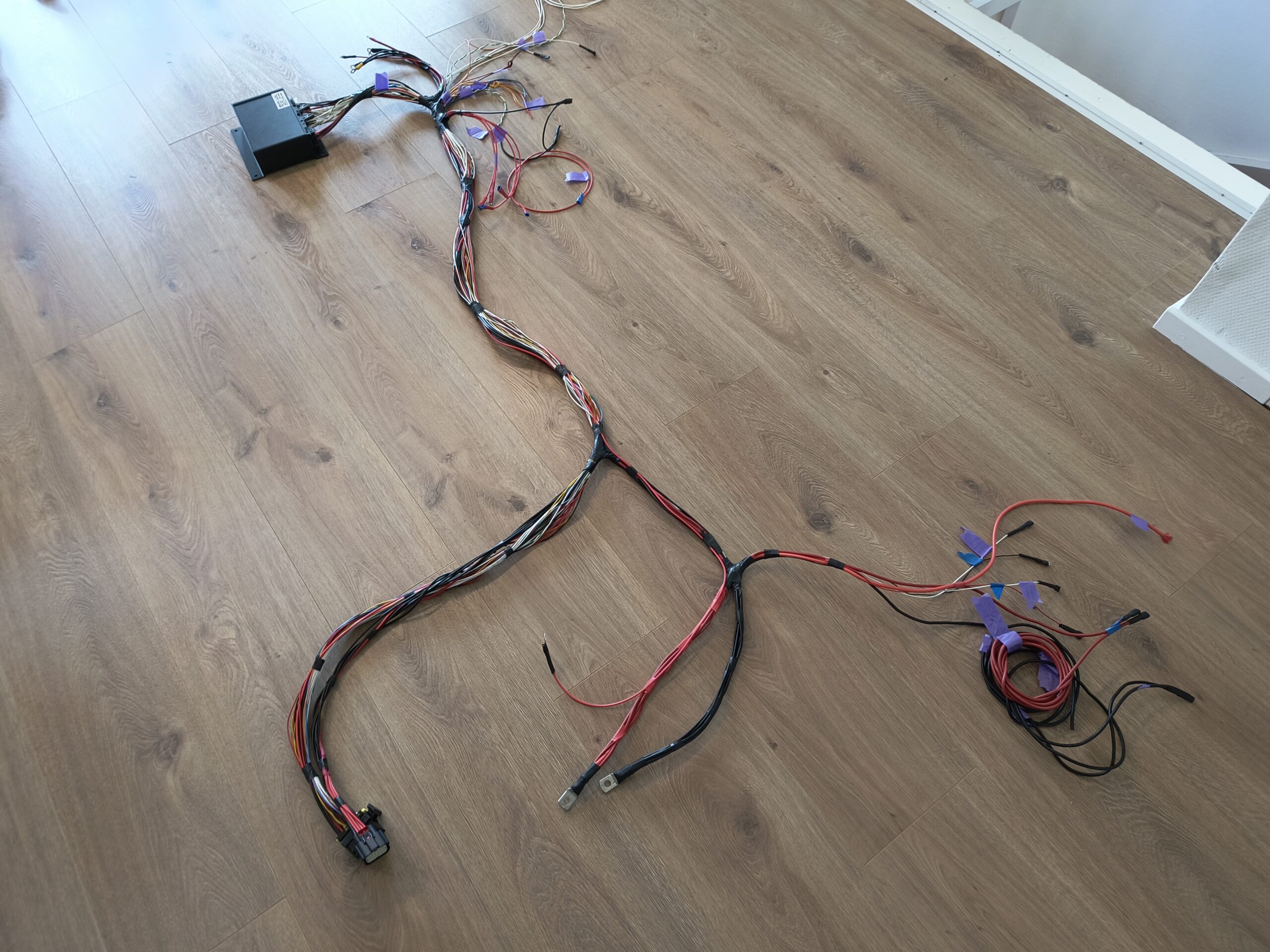

We built a complete wiring loom to link all of the sensors inputs and actuator outputs from the Kubota engine so that they could link to the DID1 standalone ECU.

The project was rather complex, although we had schematics from the manufacturer these actually contained quite a few faults which made the project harder than it needed to be.

After some fault finding we were able to wire everything correctly and get the engine to fire up.